900A Portable Multi Gas Detector is used for portable and rapid detection of multiple gas concentrations, temperature and humidity measurement, and alarm when exceeding the standard. 2~6 gas detections can be customized. It is widely used in complex, changeable and potentially dangerous working environments, especially in situations involving multiple harmful gases and flammable gases.

Features

- Imported high-precision sensors are used;

- High-precision low-temperature drift amplifiers and stable power supply processing circuits are used;

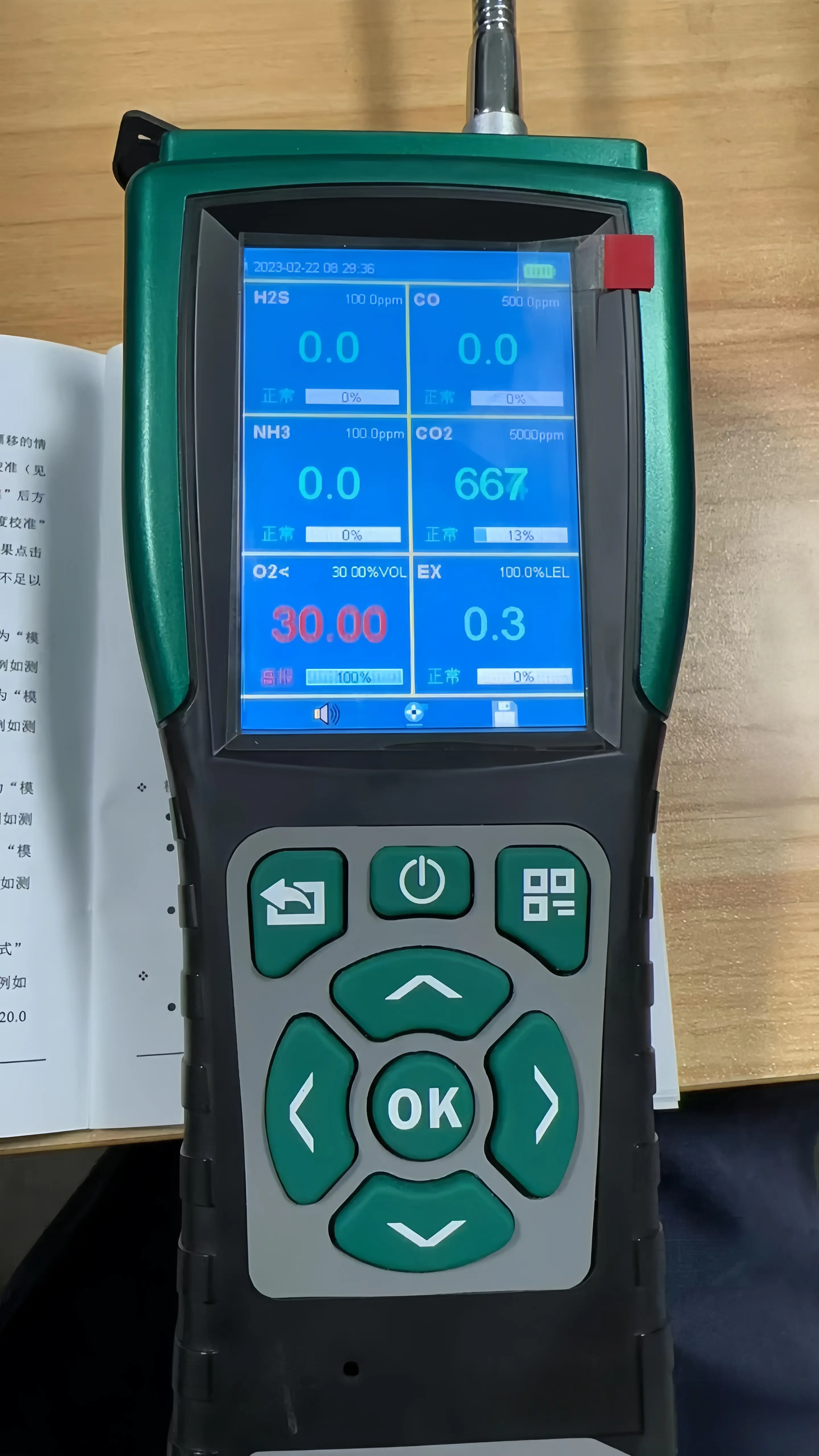

- TFT3.5 full-color display, graphic menu, providing real-time detection trend analysis charts;

- Data storage function, can store 200,000 sets of data, storage interval time is adjustable:

- USB interface high-speed data transmission, can download and print data:

- Comply with explosion-proof certification, explosion-proof level: ExialCT4;

- Anti-slip, waterproof, dustproof;

- Monitor the concentration of gas in the environment or confined space and alarm;

- With self-calibration function, zero point calibration function, multi-point calibration function;

- With temperature and pressure compensation;

Specifications

| Detection of gases | Toxic, harmful and flammable gases |

| Detection method: | built-in pump suction, flow rate 500 ml/min |

| Display mode: | 3.5-inch high-definition color screen display, 8-button operation |

| Detection accuracy: | ≤±2% (F.S) |

| Linearity: | ≤±2% |

| Repeatability: | ≤±2% |

| Alarm mode: | sound and light alarm, vibration alarm, visual alarm, sound and light + vibration + visual alarm, closed alarm |

| Response time: | T90≤20 seconds |

| Recovery time: | ≤30 seconds |

| Working power supply: | DC3.6V |

| Sensor life: | electrochemical principle is greater than 2-3 years, oxygen 2 years or 6 years optional, infrared principle 5-10 years, catalytic combustion 3 years, thermal conductivity 5 years |

| Use environment: | temperature -40℃~+70℃; relative humidity ≤0-99%RH (built-in filter can be used in high humidity or high dust environment) |

| Sample gas temperature: | -40℃~+70℃, optional high-temperature sampling cooling filter handle or high temperature and high humidity pretreatment system can detect 800℃ Smoke concentration |

| Temperature measurement: | -40℃~+120℃ (optional) Accuracy 0.5℃ |

| Humidity measurement: | 0-100%RH (optional) Accuracy 3%RH |

| Battery capacity: | 3.6VDC, 5400mA large-capacity rechargeable polymer battery, with overcharge, over-discharge, overvoltage, overheating, and short-circuit protection functions |

| Data storage: | Standard 100,000 data capacity, larger capacity can be customized, support local viewing or data export, free host computer communication software. The storage function is closed by default, can be set to open, and the storage time interval can be set arbitrarily |

| Communication interface: | USB (charging and communication), RS232, infrared communication, automatic identification |

| Printer: | Optional, external micro wireless infrared thermal printer |

| Interface language: | English |

| Explosion-proof type: | intrinsically safe type |

| Explosion-proof mark: | Exia II CT6 |

| Protection level: | IP66, rain and water splash, dustproof |

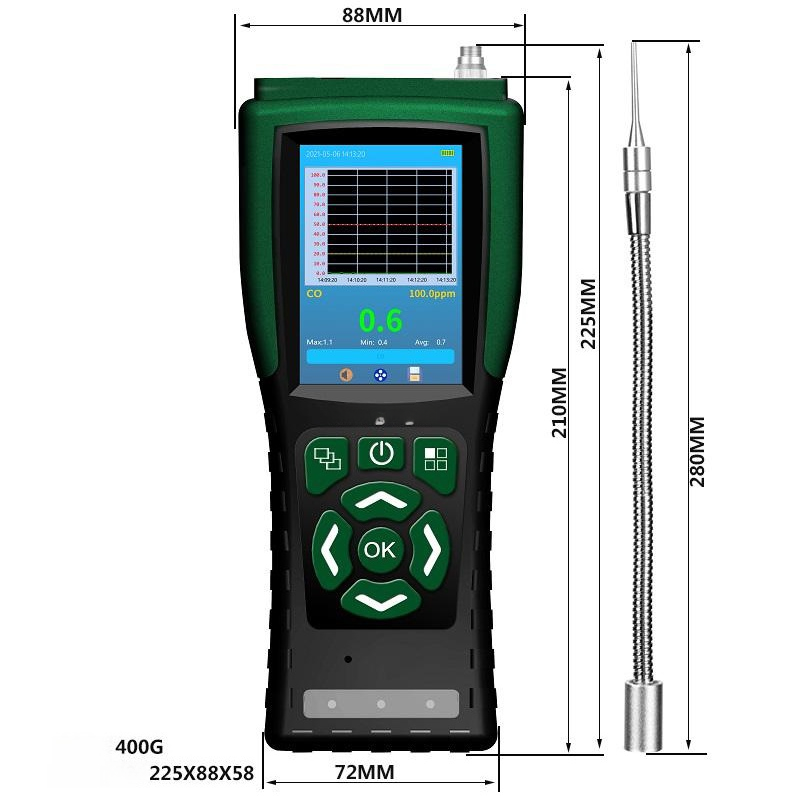

| External dimensions: | 225*88*58mm (L×W×H) |

Portable gas detector sampling probe selection:

| Name | Specifications | Notes |

| Stainless steel sampling handle (304) | Length 0.4 m, with micro stainless steel dust filter | Equipped with 1 meter hose, which can be extended, maintainable, for gas sampling within 80℃ |

| Stainless steel sampling handle (316L) | Length 1.2 m, with micro stainless steel dust filter | Equipped with 1 meter hose, which can be extended, maintainable, for gas sampling within 200℃ (short time) |

| High temperature sampling filter cooling handle 400℃ | Sampling probe 0.3 m, 400°C, with filter | 2 meter cooling hose, filters water vapor and dust (must be equipped for portable smoke detection) |

| High temperature sampling filter cooling handle 800℃ | Sampling probe 0.7 m, 800°C, with filter | |

| High temperature sampling filter cooling handle 1300℃ | Sampling probe 1.0 m, 1300°C, with filter |

Applications of Portable Multi Gas Detector

Portable Multi Gas Detector is widely used in complex, changeable and potentially dangerous working environments, especially those involving multiple harmful gases and flammable gases. Here are a few typical practical application conditions for your reference:

1. Confined space operations

Application scenarios: underground pipelines, tunnels, sewage wells and other closed environments.

Gas risks:

- Insufficient or excessive oxygen (O₂) content;

- Highly toxic hydrogen sulfide (H₂S);

- Risk of carbon monoxide (CO) poisoning;

- Risk of accumulation and explosion of combustible gases (LEL, such as methane).

Specific applications:

Before entering the underground well, the staff lowers the Portable Multi Gas Detector to the bottom. The real-time data of the instrument is transmitted to the monitoring end of the personnel on the well to monitor the gas content in real time. Only after confirming safety can the personnel enter, and the process is monitored in real time and alarms are given.

2. Inspection of petrochemical and refining enterprises

Application scenarios: petrochemical plant storage tank area, production equipment area, loading and unloading area, etc.

Gas risks:

- Volatile organic compounds (VOC);

- Combustible gases (such as ethane, ethylene, propane, etc.);

- Hydrogen sulfide (H₂S);

- Changes in oxygen (O₂) concentration.

Specific applications:

Inspectors carry Portable Multi Gas Detector to conduct safety inspections regularly or irregularly. If gas abnormalities are found, the alarm will be immediately sounded. The instrument uses triple alarms of sound, light, and vibration to remind personnel to evacuate dangerous areas. And take emergency measures in time to prevent the accident from expanding.

3. Firefighting and emergency rescue

Application scenarios: On-site investigation and post-disaster rescue after fire accidents; Chemical plant and laboratory leakage accident disposal.

Gas risks:

- Explosion risk caused by combustible gas leakage;

- Excessive carbon monoxide (CO) concentration;

- Highly toxic gases such as hydrogen cyanide (HCN);

- Low or high oxygen (O₂) concentration;

- Corrosive and toxic gases such as sulfur dioxide (SO₂).

Specific application:

Firefighters or emergency rescue personnel carry Portable Multi Gas Detector into the accident site to monitor the on-site gas environment in real time. Ensure operational safety and rescue efficiency, and assist in quick on-site decision-making.

4. Underground mining

Application scenarios: underground operations in coal mines, metal mines, and non-metallic mines.

Gas risks:

- Methane (CH₄) and other flammable and explosive gases;

- Hydrogen sulfide (H₂S), carbon monoxide (CO);

- Risk of suffocation due to insufficient oxygen;

- Long-term accumulation of toxic or suffocating gases.

Specific application:

Underground workers carry Portable Multi Gas Detector into the working surface to continuously detect the gas content in the working area and underground passages. If an abnormality occurs, an alarm will be immediately issued and an emergency plan will be activated.

5. Municipal sewage treatment and pipe network maintenance

Application scenarios: sewage treatment plants, biochemical pools, pumping stations; daily inspection and maintenance of municipal drainage pipe networks.

Gas risks:

- Excessive concentration of hydrogen sulfide (H₂S);

- Methane (CH₄) is flammable and explosive;

- Risk of suffocation caused by insufficient oxygen;

- Ammonia (NH₃) and other corrosive gases.

Specific applications:

Maintenance personnel use Portable Multi Gas Detector to monitor the working space in real time before entering the work site and during the work process to prevent gas poisoning and explosion accidents.

6. Chemical laboratories and scientific research sites

Application scenarios: laboratories of universities and scientific research institutions; laboratory research and development laboratories of pharmaceutical companies.

Gas risks:

- Vapours of flammable and explosive organic solvents;

- Toxic and harmful gases such as ammonia (NH₃) and chlorine (Cl₂);

- Danger caused by abnormal oxygen content;

- Volatile organic compound (VOC) pollution exceeds the standard.

Specific applications:

Laborators carry Portable Multi Gas Detector before and during chemical experiments to ensure the breathing safety of personnel in real time and ensure that the experimental environment meets safety standards.

7. Ship and offshore platform operations

Application scenarios: closed cabins, oil tanks, fuel tanks of ships; offshore oil drilling platforms.

Gas risks:

- Combustible gases (methane, ethane, diesel volatiles);

- Lack or excess of oxygen;

- Excessive hydrogen sulfide (H₂S);

- Carbon monoxide (CO) leakage.

Specific applications:

Before workers go down to the cabin or enter the dangerous area, use the six-in-one portable gas detector to detect the space, and monitor in real time during the operation after confirming safety. Especially in long voyages, the instrument provides continuous safety protection.

The Portable Multi Gas Detector integrates multiple functional advantages such as gas monitoring, real-time alarm, data recording, wireless communication, and strong environmental adaptability. It can flexibly cope with the operating environment with complex gas composition, closed space, and high risk factor in the above different working conditions.

For this reason, this detector has become one of the important equipment indispensable for protecting the life safety of personnel in various dangerous operation scenarios.

If you need to purchase a Portable Multi Gas Detector, please feel free to contact our sales engineer!