This stainless steel gas monitoring system is an online monitoring device that integrates sampling, cooling, dust removal, drying, oil filtration, pressure reduction, Restrict flow, analysis, and signal transmission. It samples flue gas or the gas being measured from the site, dehumidifies, filters dust, and maintains a constant temperature and humidity within a specified range, enabling the gas analyzer to detect concentrations properly. The entire process is automated, requiring no human intervention.

The gas pretreatment system is suitable for applications with low dust content, high temperature, and high humidity. Applications with high levels of dust and tar require a tar treatment system.

Functions and Features

Online gas analyzers typically require clean samples free of interfering components. Under normal circumstances, samples must be within specified temperature, pressure, and flow ranges. Therefore, the basic tasks and functions handled by this system are summarized as follows:

- Stainless steel gas line sampling, dust removal, water and humidity removal, and gas-liquid separation;

- Maintaining gas flow regulation, including rapid flow and analytical circuits;

- Pressure regulation, including pressure reduction, suction, and stabilization;

- Removing harmful substances, including components that are harmful to analyzer probes and interfering components that affect measurement.

The Gas Monitoring System contains two stainless steel filters with precision filter elements to filter dust and particulate matter. One is the primary filter, while the other is the backup filter. The backup filter can be manually switched to the backup filter when replacement is necessary.

The system features a high-pressure gas backflush function for the sampling line. A solenoid valve controlled by the detector controls the gas line switching, backflushing compressed gas into the sampling line to ensure unobstructed flow.

The system does not utilize an air pump, electronic condenser, instrument air ejector, or vortex dehumidifier. Physical methods are used to pump air and cool and remove water, ensuring system stability, reliability, and safety.

Standard gas inlet ports and a switching valve facilitate zeroing and calibration of the detector.

Specifications

| Housing Material: | 304 stainless steel; |

| Gas Pipe Material: | 304 stainless steel tube |

| External Dimensions: | 890 × 340 × 1450 mm (L × W × H) |

| IP Rating: | Enclosure IP34, internal detector IP65 |

| Instrument Weight: | 80 kg |

| Ambient Operating Temperature: | 0°C-50°C |

| Ambient Operating Humidity: | <95% RH |

| Sample Gas Input Temperature: | <1200°C at the front end, <60°C before entering the pretreatment chamber. |

| Sample Gas Flow Rate: | Sampling flow rate approximately 120 L/H |

| Filter Accuracy: | 1-5 microns |

| Sample Gas Output Temperature (Cooling and Dehumidification): | 4-8°C (measured at an ambient temperature of approximately 25°C) |

| Sample Gas Port Dimensions: | Φ6 ferrule connector |

| Instrument Air (Compressed Gas) Port Dimensions: | Φ6 ferrule connector |

| Drain and Exhaust Return Port Dimensions: | Φ8 ferrule connector |

| Standard Gas Port: | Φ6 quick-tight connector |

| Instrument Air Pressure Requirements: | ≥0.5 MPa, <0.9 MPa |

| Operating Voltage: | 24V DC power supply |

| Power: | <40W |

| Detector Signal Output Method: | RS485 digital signal (MODBUS RTU protocol) and three-wire 4-20 mA analog signal |

| Warm-up Time: | <5 minutes |

Stainless Steel Gas Monitoring System Process Flow

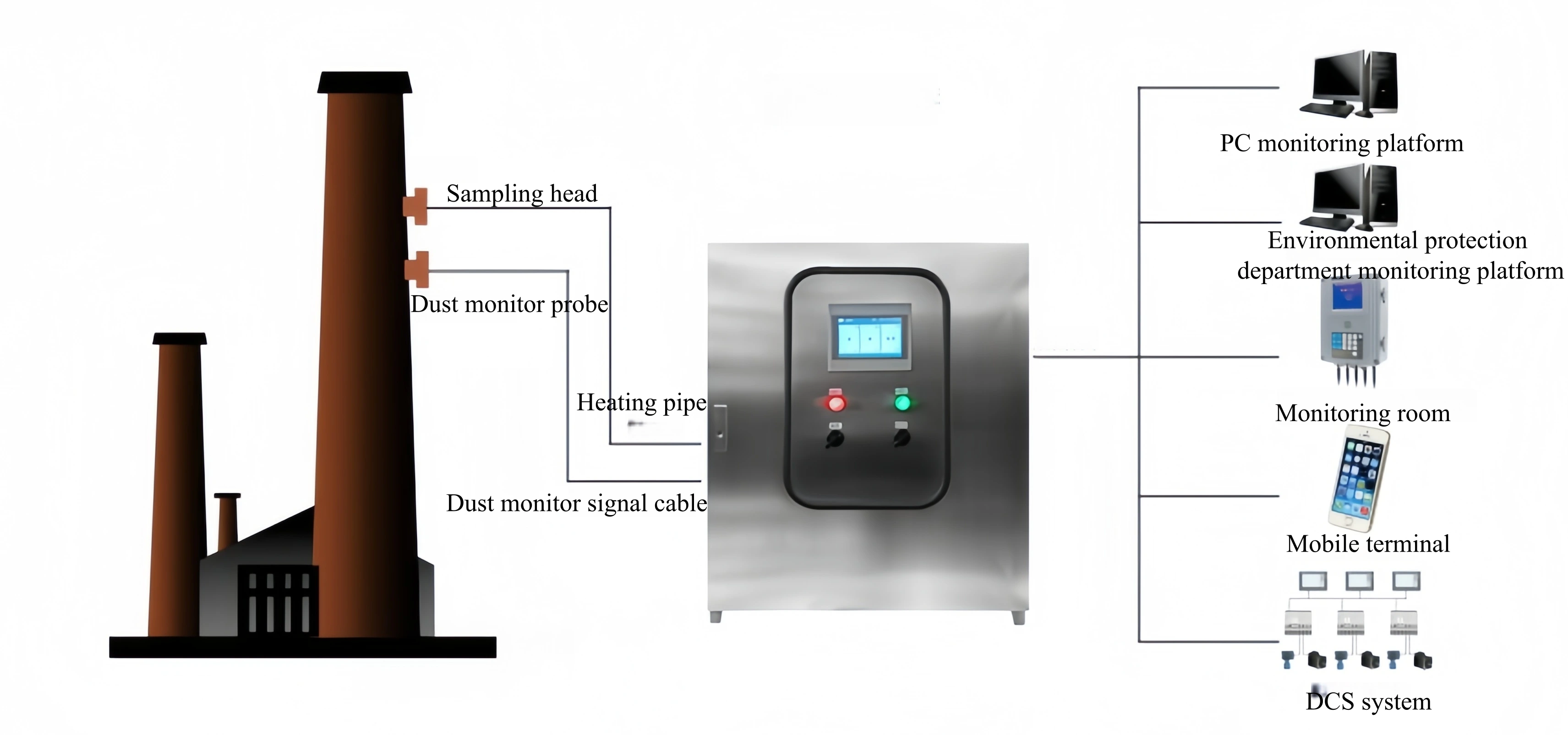

The system includes a sampling unit, a sample gas pretreatment unit, a gas analyzer detection unit, a signal transmission unit, a calibration unit, and a backflush unit.

The sampling unit is installed directly on the process pipeline. A sampling pump and explosion-proof heated pipe are used to transport the sample gas to the monitoring cabinet. The sample gas is then filtered and condensed before being supplied to the gas analyzer for analysis. The analyzed sample gas is then discharged.

What Is a Fixed Gas Monitoring System?

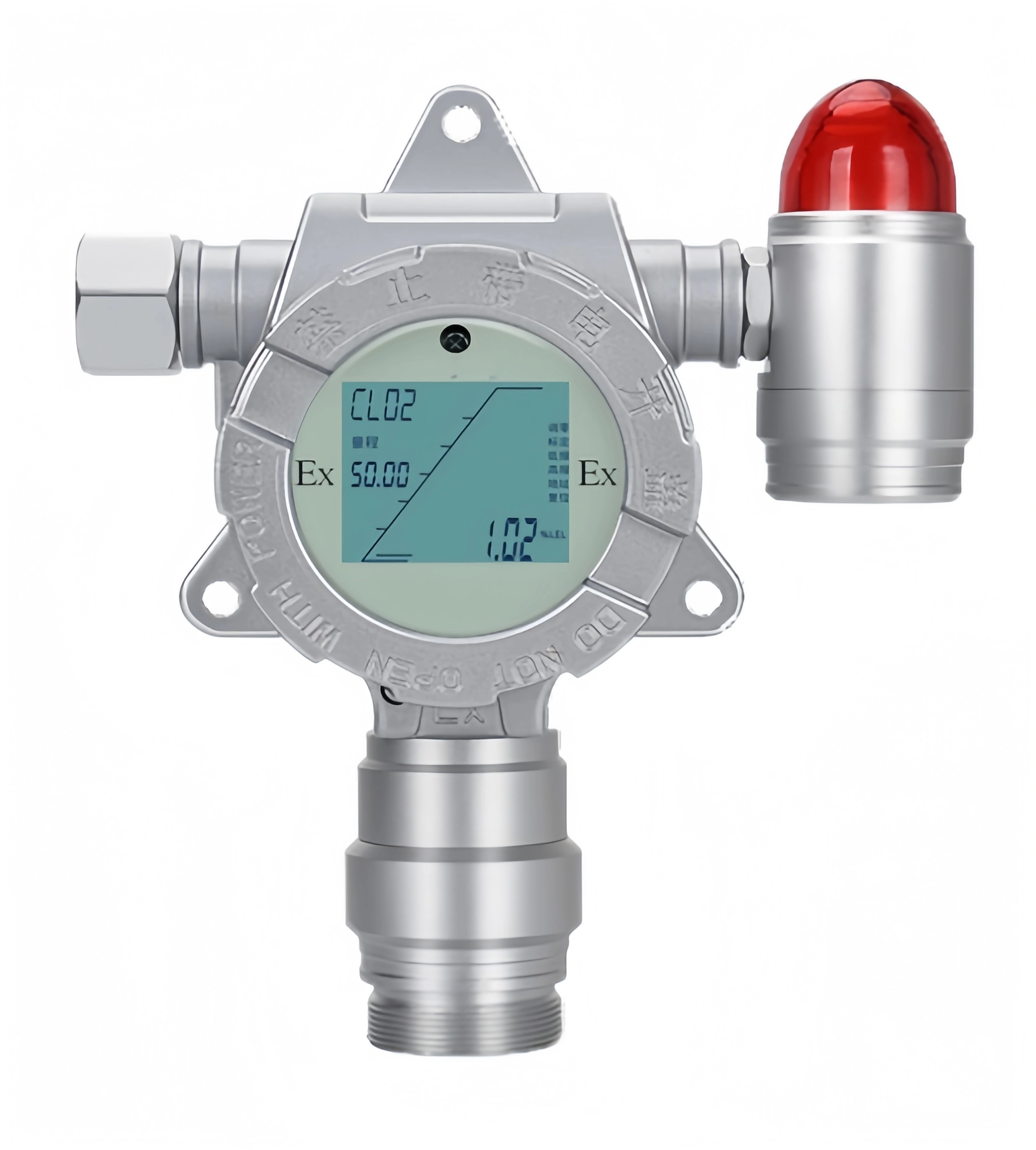

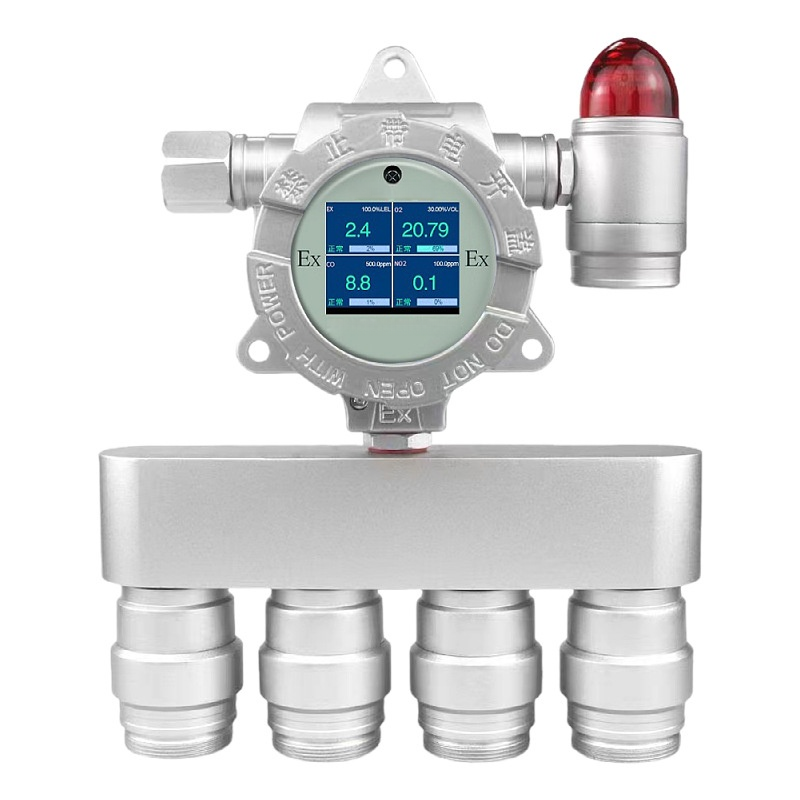

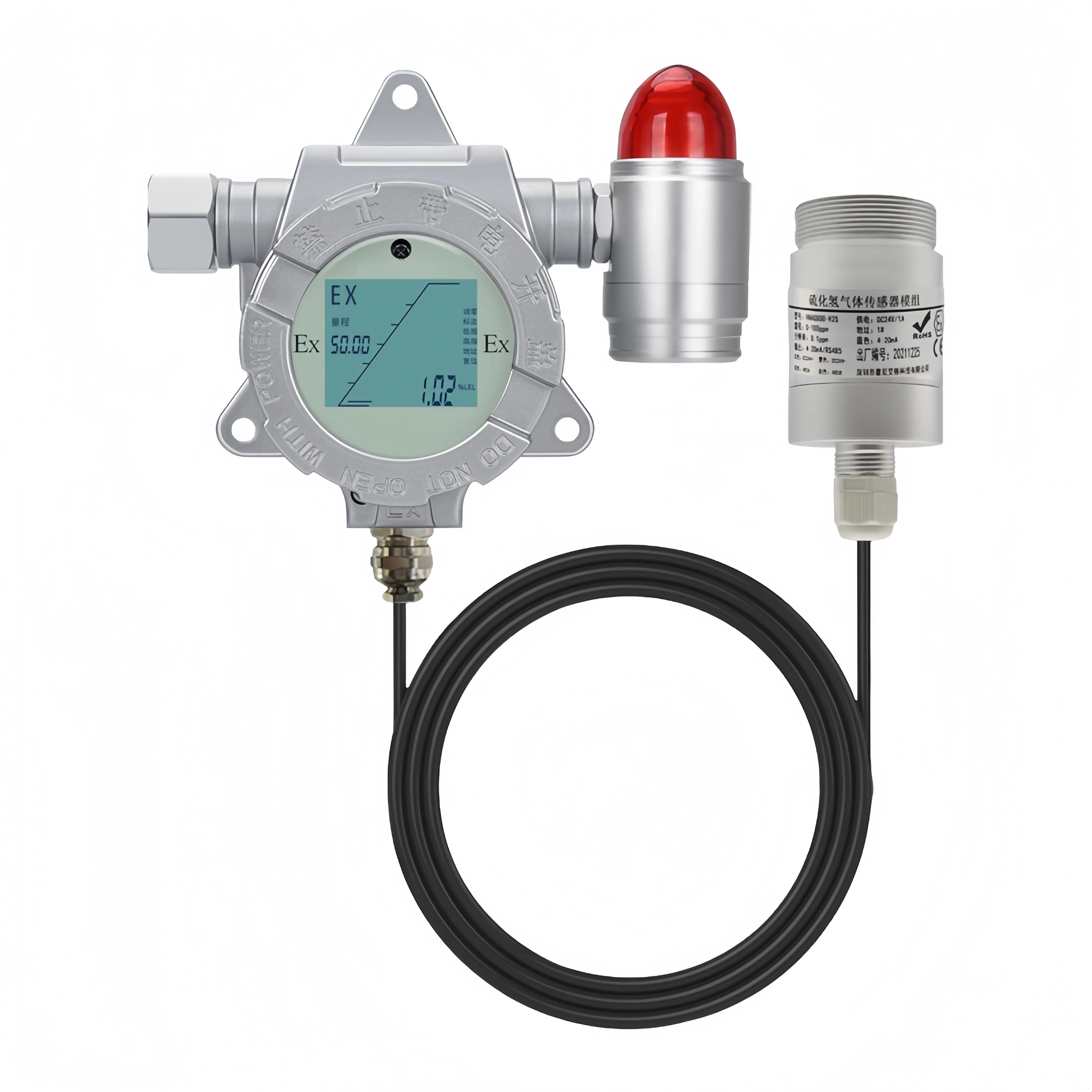

A fixed gas monitoring system is a system installed at a specific location for continuous analysis and monitoring of the gas being measured. Once it detects gas concentrations exceeding a preset safety threshold, it issues an audible and visual alarm, alerting personnel to take emergency action. This equipment typically consists of a detector, an alarm, and auxiliary circuitry, enabling real-time monitoring and ensuring a safe working environment.

What is a gas pretreatment system?

The role of the gas sample conditioning system is to ensure that the gas analyzer obtains a representative process sample with minimal lag time, and that the sample’s conditions (humidity, pressure, flow rate, and cleanliness) meet the gas analyzer’s required operating conditions.

The effectiveness of an online gas analyzer often depends not on the analyzer itself but on the integrity and reliability of the sampling system. This is because, no matter how complex and precise a gas analyzer is, its analytical accuracy is limited by the sample’s representativeness, real-time nature, and physical condition.

In fact, sampling systems often encounter more problems than the gas analyzer itself, and require more maintenance than the gas analyzer itself. Therefore, the role of the sampling system should be prioritized, at least on an equal footing with the analyzer.

Optional Gas Detectors

The Sino-Inst Stainless Steel Gas Monitoring System utilizes intelligent sensor technology, offering fast response times, high measurement accuracy, and excellent stability and repeatability. It is suitable for flue gas and exhaust gas treatment from various combustion equipment, including boilers, furnaces, and kilns, as well as for gas sampling and purification in environmental emissions applications.

If you require a custom gas monitoring system, please feel free to contact us!