The Online Exhaust Gas Monitoring System continuously monitors multiple flue gas and exhaust gas parameters, including sulfuric acid mist, hydrochloric acid mist, and particulate matter concentration. Various parameters can be displayed. Equipped with RS485 and 4-20mA interfaces, the system provides digital and analog outputs and can be connected to a DCS system based on user requirements. The system also supports multiple communication methods, including MODBUS, GPRS, CDM, ADSL, and Ethernet.

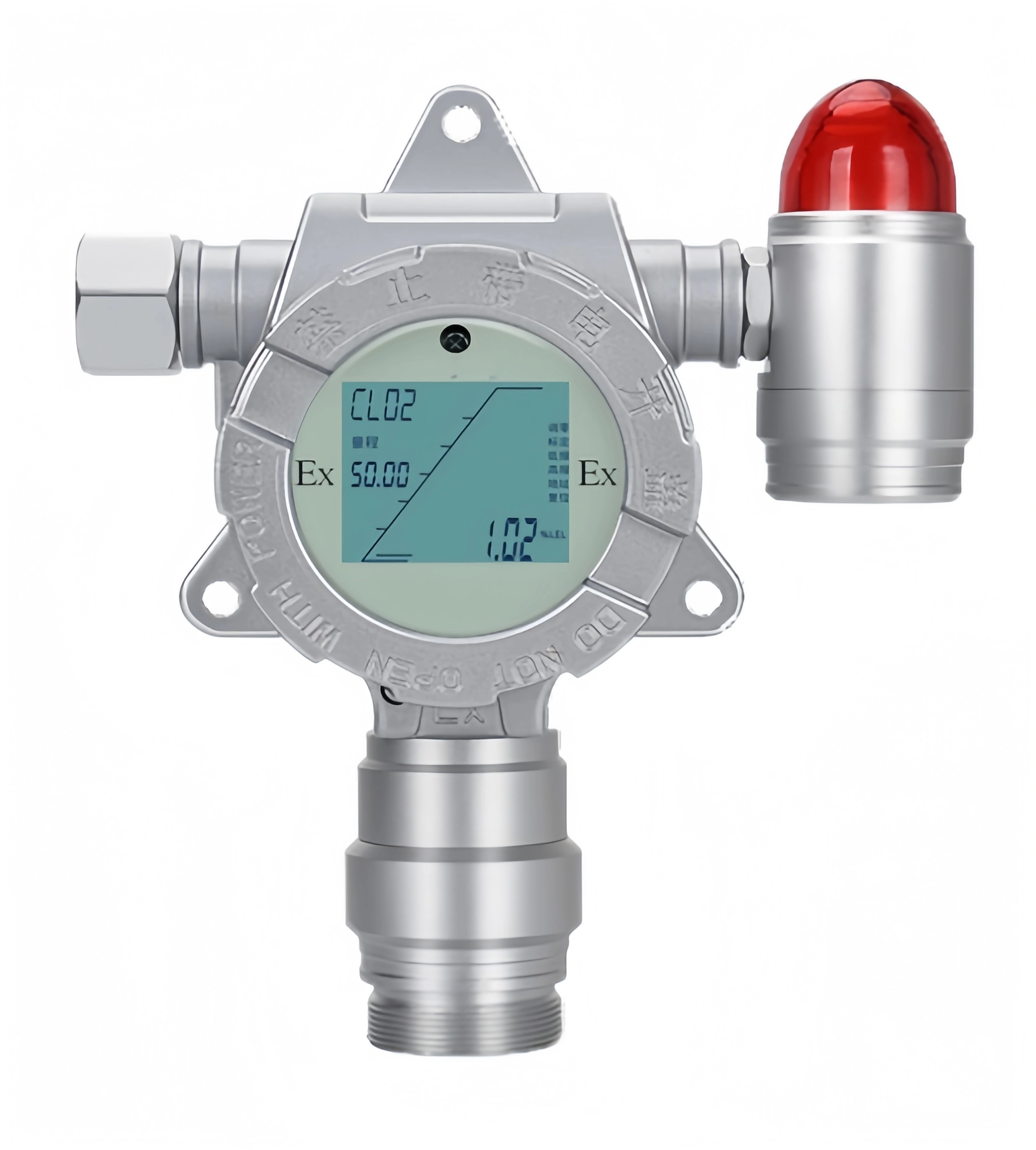

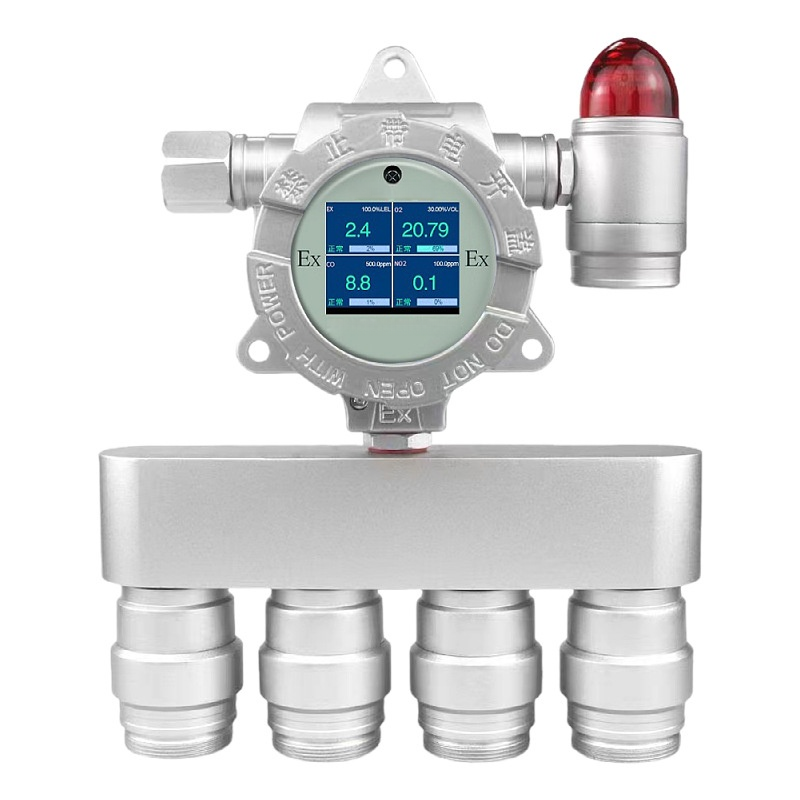

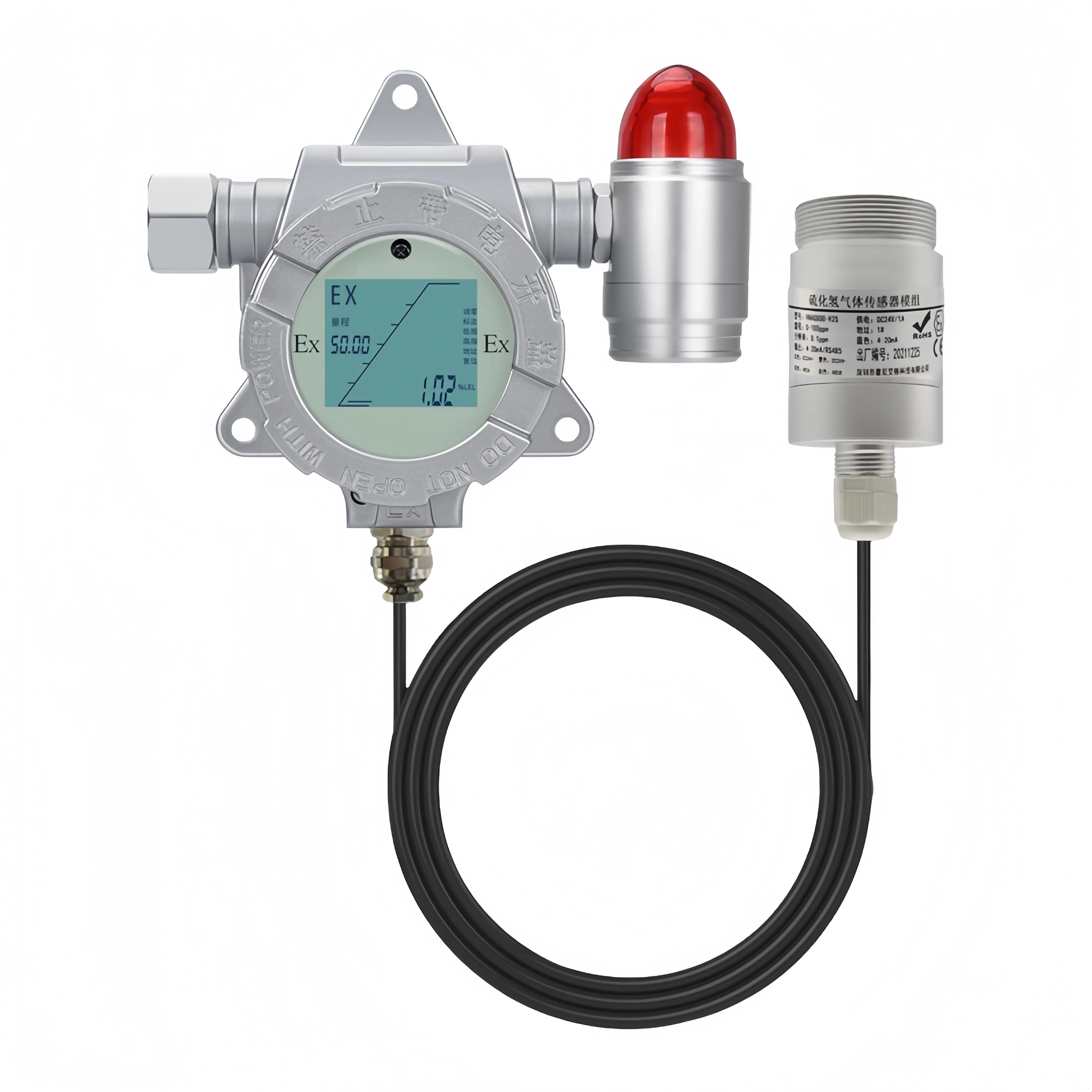

Sino-Inst’s online exhaust gas monitoring system utilizes internationally advanced and proven technologies, tailored to the actual site conditions of high temperature, high humidity, high dust, and high corrosion, and features specialized safety designs specifically designed for use in explosive and hazardous industrial environments such as flue gas and exhaust gas. It utilizes a unique positive pressure isolation cabinet, electrical signal barrier technology, and a signal integration explosion-proof enclosure. It has passed national certification and obtained a national explosion-proof certification.

Features

- The system features highly integrated monitoring and comprehensive functionality. It’s easy to operate and install.

- A pre-installed high-temperature dust filter with a 10μm pore size offers a filtration efficiency of ≥99%.

- The sampling tube utilizes a constant-temperature heat tracer and an automatic temperature control system, effectively preventing the sample gas from being affected by ambient temperature.

- A compressor-based condensation system and a peristaltic pump automatically drain the sample gas. This provides rapid cooling and simultaneous gas-liquid separation, preventing liquid contamination of the sample gas composition.

- A 10μm-grade SMC oil mist filter imported from Japan is used. The peristaltic pump automatically drains the sample gas.

- Imported high-performance gas sensors provide online analysis and real-time monitoring, enabling simultaneous monitoring of multiple gases.

- An embedded 32-bit, low-power microprocessor provides fast response times, high measurement accuracy, and excellent stability and repeatability.

- Data storage and analysis systems and remote data transmission systems (RS485, RTU433, GPRS, and TCP/IP network transmission are optional).

- Standard backflush and standard gas calibration ports facilitate easy maintenance.

Specifications

| Power Input: | 220VAC |

| Working Power: | 35-40W |

| Sensor Type: | Electrochemical; |

| Gas Type: | Sulfuric acid mist, hydrochloric acid mist, particulate matter, etc. |

| Sampling Method: | Pump suction; |

| Gas Range: | Sulfuric acid mist 0-100mg/m³, hydrochloric acid mist 0-100mg/m³, particulate matter 0-100mg/m³ |

| Accuracy: | ≤±3%FS; |

| Resolution: | 0.1mg/m³ |

| Repeatability: | ≤±3%FS |

| Zero Drift: | ≤±2%FS/6h |

| Span Drift: | ≤±5%FS/6h |

| Response Time: | T90 ≤3s; |

| Communication Method: | 4-20mA/RS485 digital signal |

| Alarm Method: | Video and audio alarm; |

| Display: | 7-inch touch screen |

| Operating Temperature: | -20~400℃ |

| Operating Humidity: | 0~90%RH (non-condensing) |

| Service Life: | Sensor (2 years), instrument (5 years) |

Online Exhaust Gas Monitoring System Process Design

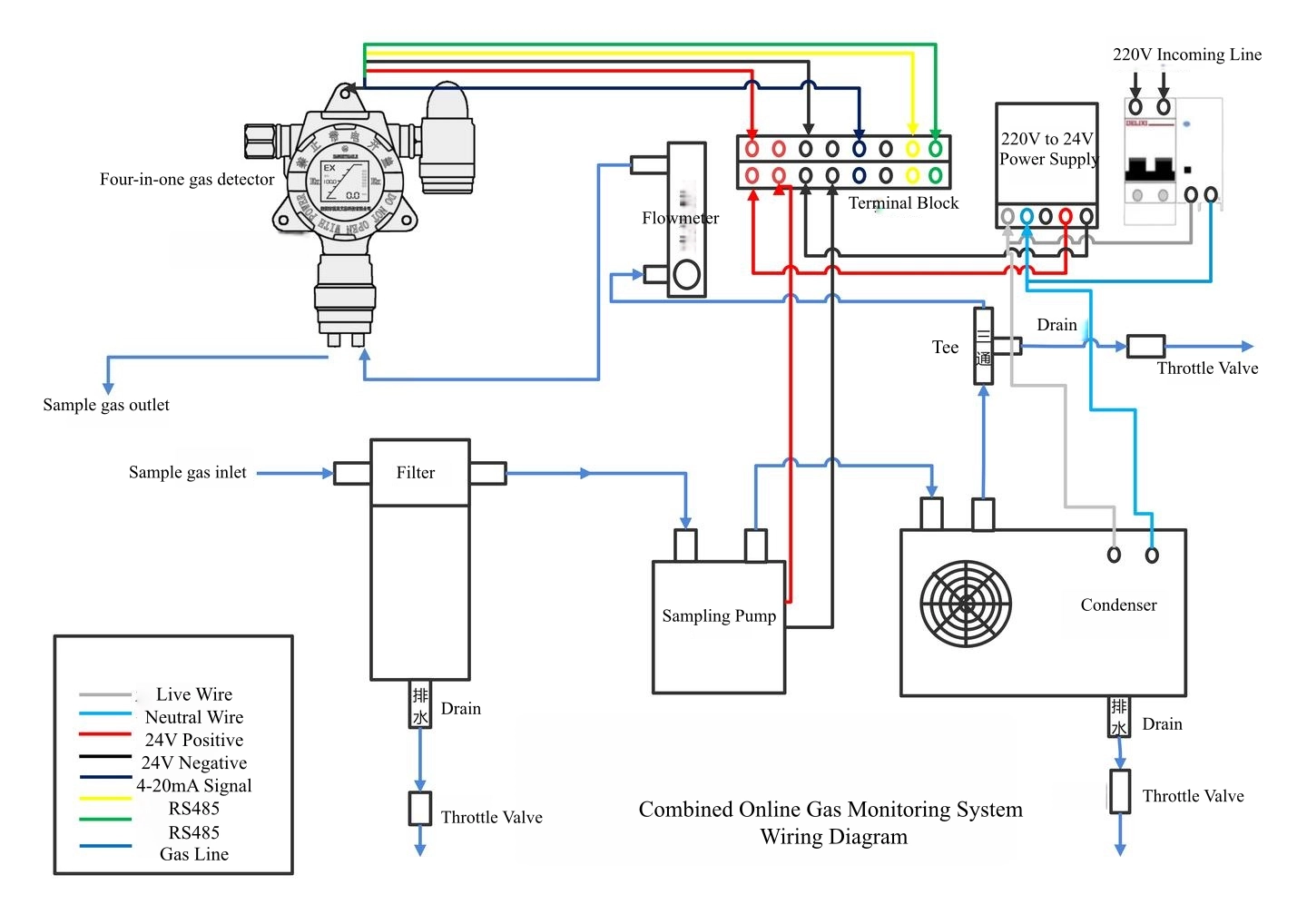

The Online Exhaust Gas Monitoring System includes a sampling unit, a sample gas pretreatment unit, a gas analyzer detection unit, a signal transmission unit, a calibration unit, and a backflush unit.

The sampling unit is installed directly on the process pipeline, using a sampling pump and explosion-proof heat-tracing pipe to transport the sample gas to the monitoring cabinet. The sample gas is then filtered and condensed before being fed to the gas analyzer for analysis. The analyzed sample gas is then discharged.

Online Exhaust Gas Monitoring System Process Flow

Online analyzers typically require clean samples free of interfering components. Under normal circumstances, the sample must be within a specified temperature, pressure, and flow range. Therefore, the basic tasks and functions handled by this system are summarized as follows:

Stainless steel gas line sampling, dust removal, water and moisture removal, and gas-liquid separation;

Maintaining gas flow regulation, including rapid flow and analysis circuits;

Pressure regulation, including pressure reduction, suction, and stabilization.

Removal of harmful substances, including components that are harmful to the analyzer probe and interfering components that affect measurement.

Based on the customer’s operating conditions and usage requirements, the pretreatment process is designed as follows:

- Boiler flue gas is routed on-site through a φ8*10cm 316 stainless steel pipe. The boiler flue and stainless steel pipe are connected by welding or flanges. The tail end requires an M10 internal thread or a peg-shaped connector to connect to our air inlet pipe.

- Because the operating conditions within the pipe can reach temperatures as high as 1300°C, the sampling pipe must be at least 10 meters long.

- The heated gas enters a U-shaped spiral condenser dryer. The gas is instantly cooled to room temperature, and condensed water droplets are automatically discharged by a peristaltic pump.

- The condensed gas enters a dust and moisture filter for secondary filtration.

- The secondary dried and filtered gas enters a flow meter and is fed to the detector probe for testing at a flow rate of 500ml/min.

- After testing, the exhaust gas is absorbed and discharged.

- The entire system is cabinet-style, with optional rollers and mounting brackets.

- The entire system gas line is made of 304 stainless steel pipes, and all metal joints are made of 304 stainless steel.

Exhaust Gas Monitoring System Optional Gas Analyzer

The Sino-Inst Exhaust Gas Monitoring System is suitable for online monitoring of SO2, NOx (NO, NO2), and particulate matter in exhaust emissions from various stationary sources. It can also be expanded to monitor CO, CO2, and other factors. The system consists of four components: a gaseous pollutant monitoring subsystem (SO2, NOx), a particulate matter monitoring subsystem, a flue gas parameter monitoring subsystem (temperature, pressure, flow rate, humidity, and oxygen content), and a system control and data acquisition and processing subsystem.

If you require a customized Exhaust Gas Monitoring System, please feel free to contact us!