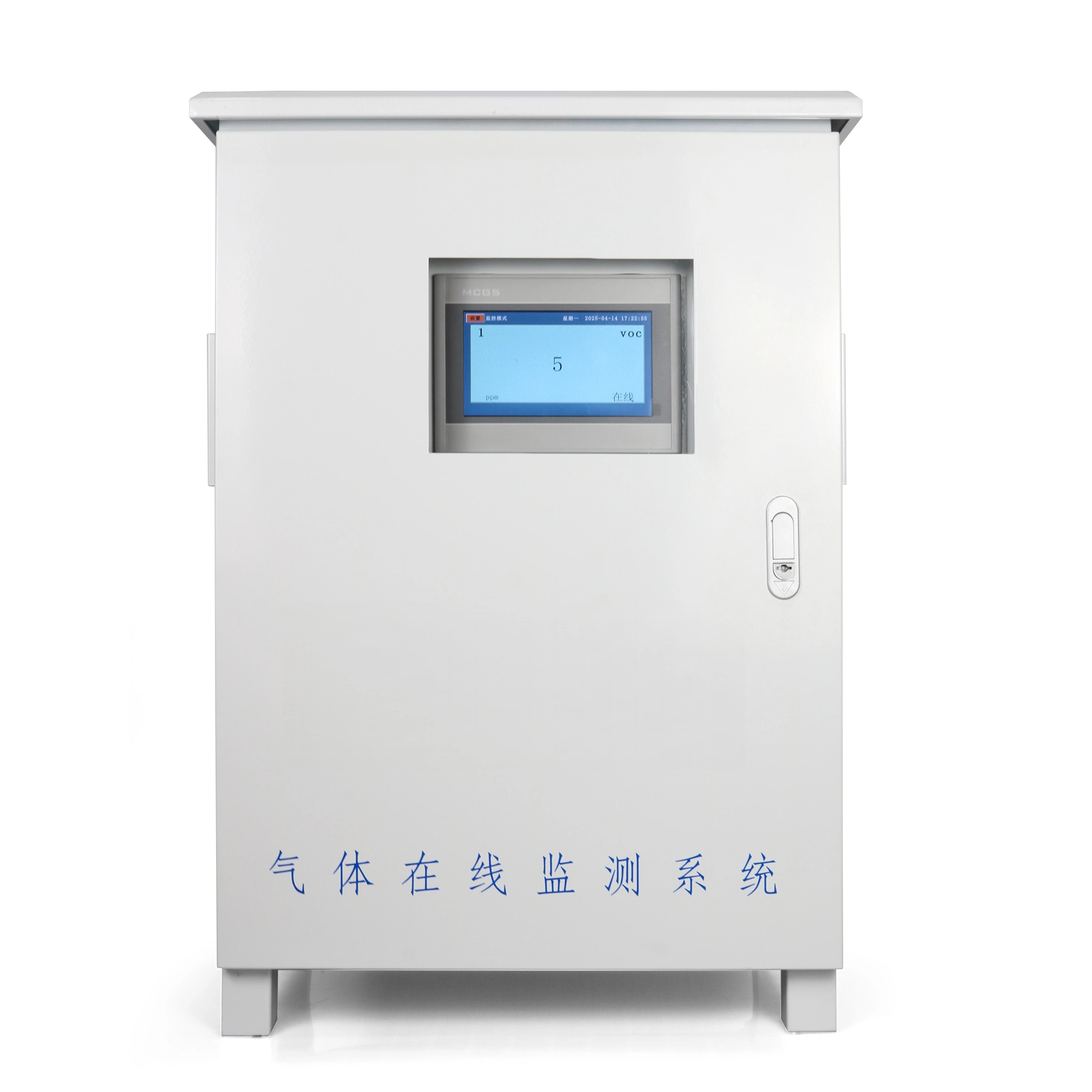

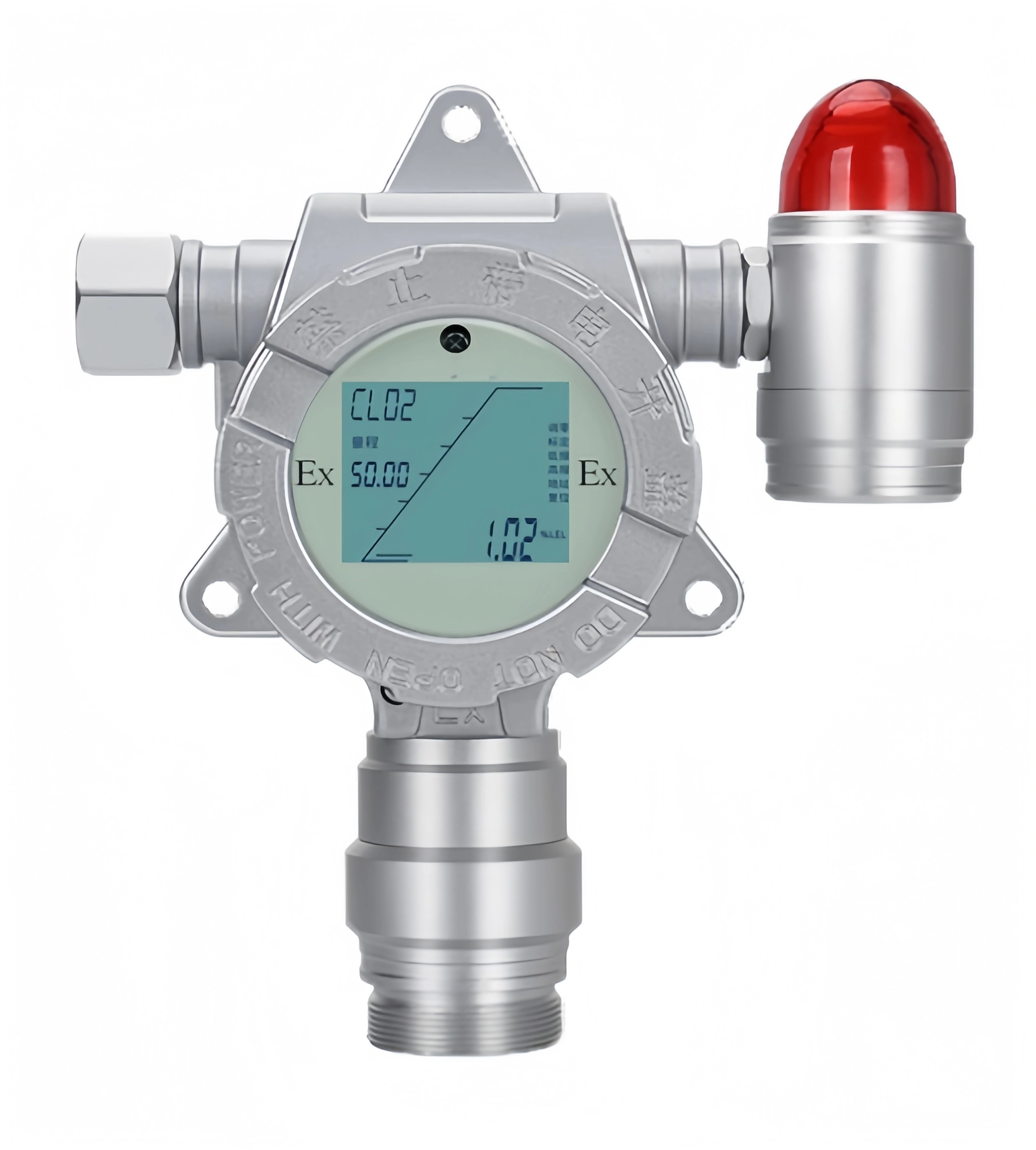

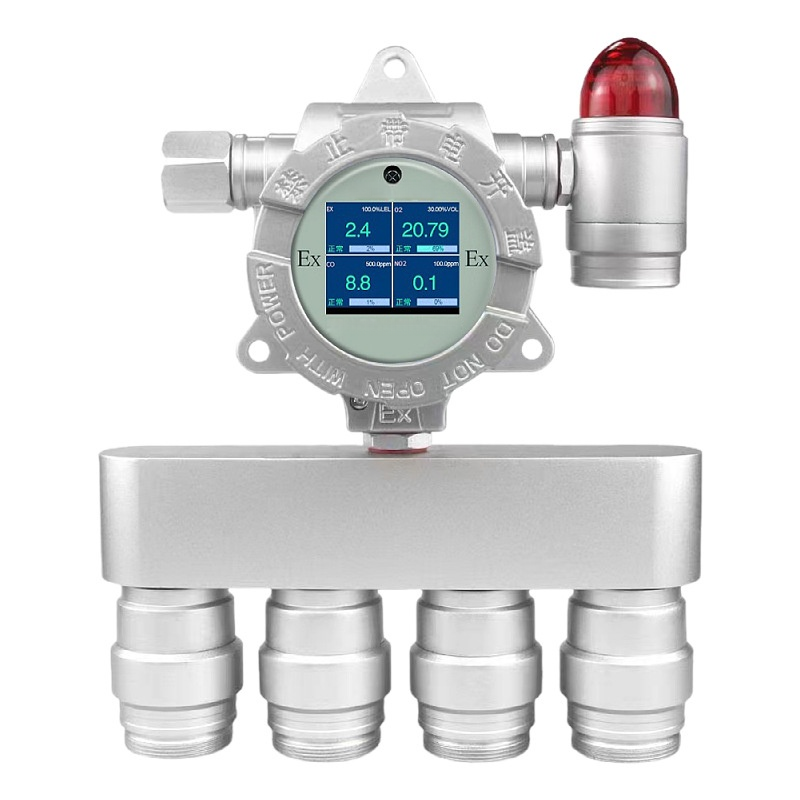

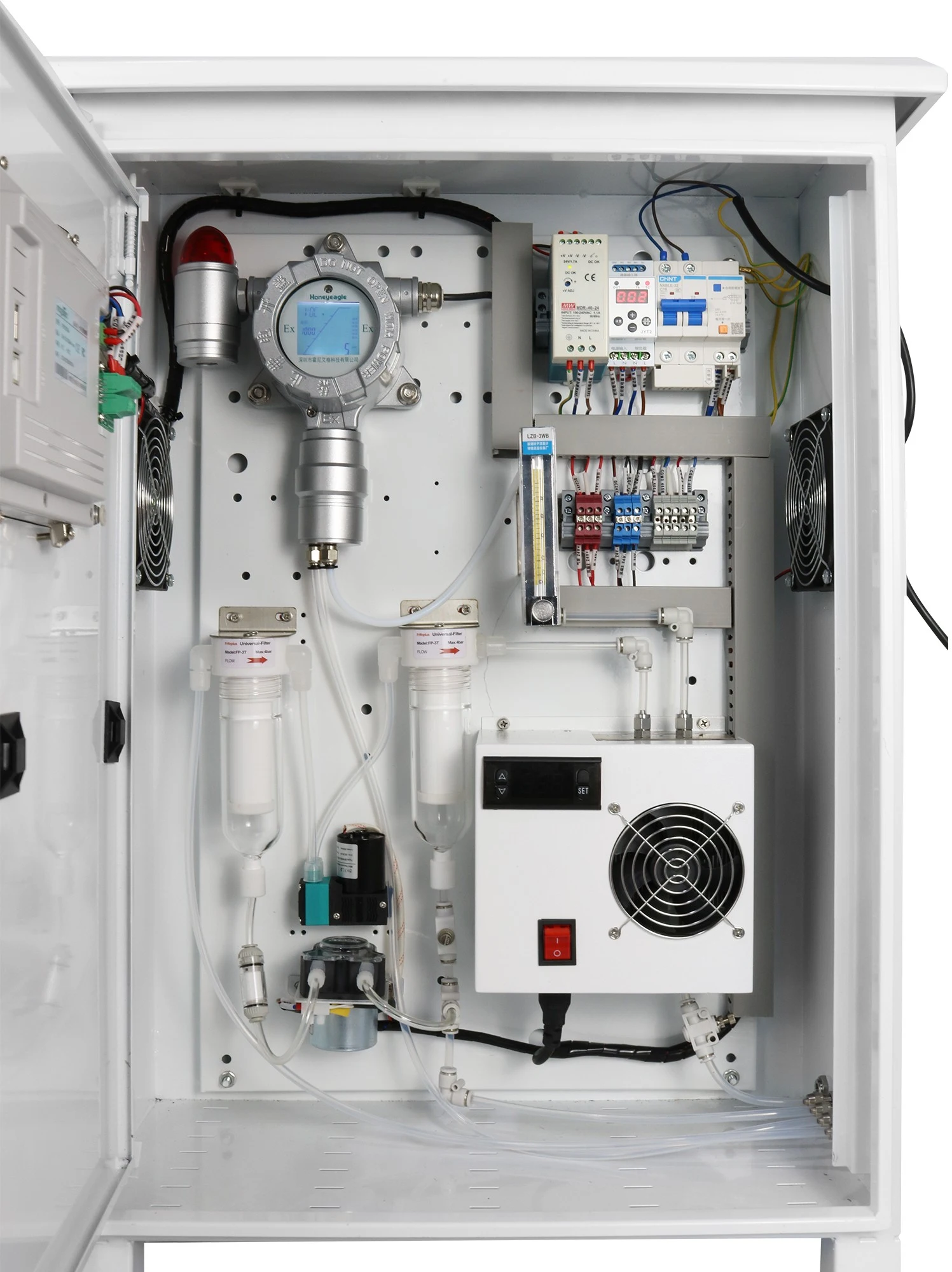

VOC monitoring system is a factory boundary/fixed source VOC online monitor independently developed and produced by our company. The sensor is an imported high-precision PID sensor. Adopts pump suction sampling method for monitoring. Has a built-in water removal and dust removal filter. It can well protect the sensor from damage. Use sound and light alarm device.

Features

- Realize high-performance automatic monitoring and anti-interference technology design;

- High precision, reliable performance, suitable for outdoor and industrial environments;

- Realize data parameter collection, automatic upload to the network platform, and automatic data release (GPRS output);

- Integrated temperature compensation technology, long-term automatic calibration technology;

- Flow control device: control real-time gas flow;

- PLC control system: data analysis, data storage, data export;

- 7-inch LCD touch screen: gas units can be switched;

- Optional: wireless transmission module 4G/Lora/WIFI/DTU, etc.;

- Adopt 32-bit high-speed processing core chip;

- The gas analyzer can be built into the chassis or externally;

- The standard sampling distance is 20 meters, and the optional maximum sampling distance is more than 40 meters;

- The standard processing temperature is 200℃℃, and the maximum processing temperature can be up to 1300°C;

Specifications

| Power: | 24VDC/220VAC |

| Working power: | 35-40W |

| Sensor type: | PID |

| Gas type: | VOC |

| Sampling method: | Pump suction type; |

| Gas range: | 0~10, 0~100, 0~1000, 0~10000ppm (range optional) (For more ranges, please contact customer service) |

| Accuracy: | ≤±2%FS; |

| Resolution: | 0.001ppm, 0.01ppm, 0.1ppm, 1ppm |

| Repeatability: | ≤±2%FS ; |

| Zero drift: | ≤±2%FS/6h ; |

| Span drift: | ≤±3%FS/6h ; |

| Response time: | T90≤3 S ; |

| Signal output: | Users can determine according to actual requirements, and the maximum transmission distance can be 2000 meters (wireless signal transmission can be optional to save installation costs) a. Three-wire 4-20mA current signal output, which can be connected to various alarm controllers, PLC, DCS and other control systems b. RS-485 digital signal output, connecting RS232 adapter card can store data on the computer (optional function) c. 2 groups of relay output: passive electric shock capacity 220VAC 3A or 24VDC 3A (optional function) d. Alarm signal output: on-site sound and light alarm, alarm sound: > 110 dB |

| Alarm method: | Sound and light alarm; |

| Display: | 7-inch touch |

| Working humidity: | 0~90%RH (no condensation) |

| Automatic drainage: | Automatic drainage according to the amount of water vapor on site |

| System heating: | Optional function to prevent freezing of pipelines in extremely cold areas |

| Sampling distance: | Standard 20 meters, optional high-power vacuum pump sampling distance greater than 40 meters. If the pressure of the measured gas is relatively large, the sampling distance is correspondingly larger. |

| Sampling flow: | 4 liters/minute (standard) |

| Dimensions: | 700 high * 500 wide * 270 thick |

Working Principle of VOC Online Monitoring System

VOCs are of many types, with great harm and difficult to prevent and control. Effective control of VOCs pollution is the key to the environmental protection and purification war.

Through the use of volatile organic compound (VOCS) online monitoring system, the processing and management capabilities of fixed pollution sources or atmospheric pollution monitoring data can be improved. Provide decision-making basis for environmental planning and environmental evaluation.

The VOC online monitoring system is powered by 220V, which is converted to 24V by the internal power converter and directly powers the VOC detector and vacuum pump.

After the internal vacuum pump actively sucks the external gas into the air pipe, it is filtered through high-efficiency dehumidification and dust removal and then sent to the professional air chamber of the VOC gas analyzer for concentration detection.

The detected concentration value will be displayed in real time on the screen of the VOC gas analyzer. At the same time, there are 4-20mA or RS485 signals for remote data transmission.

What are the Sources of VOCs?

- Process exhaust gas discharged from petrochemical plants. Such as oil refining process, petrochemical oxidation process, petrochemical storage tank production process.

- The mining, storage and transportation process of oil, coal, natural gas, etc.

- The incomplete combustion products of coal, oil, petroleum products, natural gas, wood, and tobacco.

- The smoke generated by waste incineration.

- The incompletely burned hydrocarbon substances contained in the exhaust gas emitted by motor vehicles.

- Indoor decoration and decoration materials such as paint, spray paint and its solvents, wood preservatives, coatings, plywood, etc. can release benzene, toluene, xylene, formaldehyde, phenols and other volatile organic substances at room temperature.

- The processing and use of organic pesticides, deodorants, disinfectants, preservatives, and various detergents can produce volatile organic substances such as phenols, ethers, and polycyclic aromatic hydrocarbons.

- Volatile organic substances such as various synthetic materials, organic adhesives and other organic products can produce some low-molecular organic pollutants when they are oxidized and cracked when encountering high temperatures.

- Some organic pollutants are produced when starch, fat, protein, cellulose, sugars, etc. are oxidized and decomposed.

More VOCs Monitors

Sino-Inst VOC online monitoring system performs real-time online monitoring of volatile organic compounds from fixed pollution sources in the environment. It is a professional system integration product that integrates gas sampling, gas filtration, real-time concentration display, local sound and light alarm, equipment linkage, data remote control and other functions.

There are many types of VOC online monitoring systems, and generally you need to purchase them according to your actual needs. If you need to configure a VOCs monitoring system or have related technical questions, please feel free to contact us.