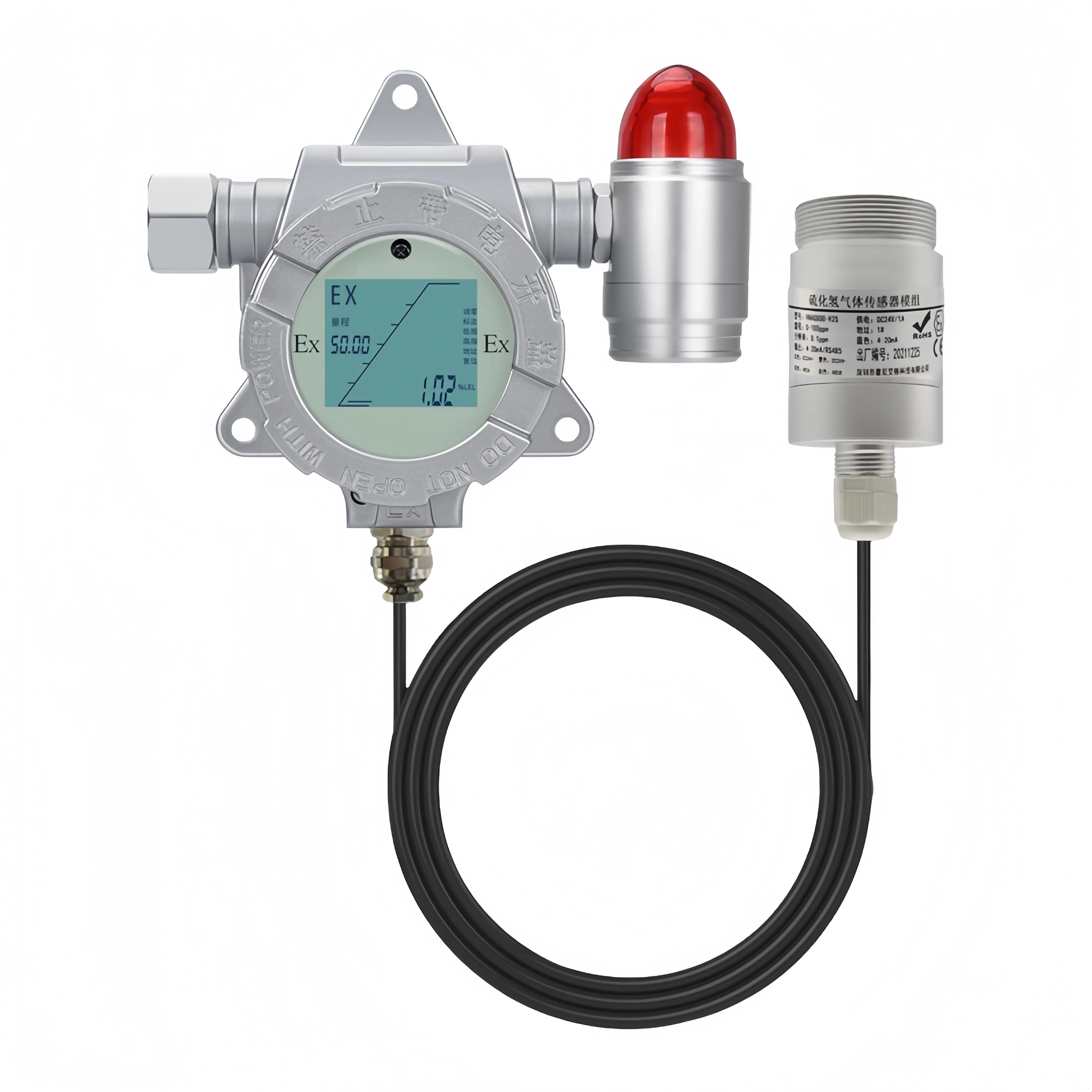

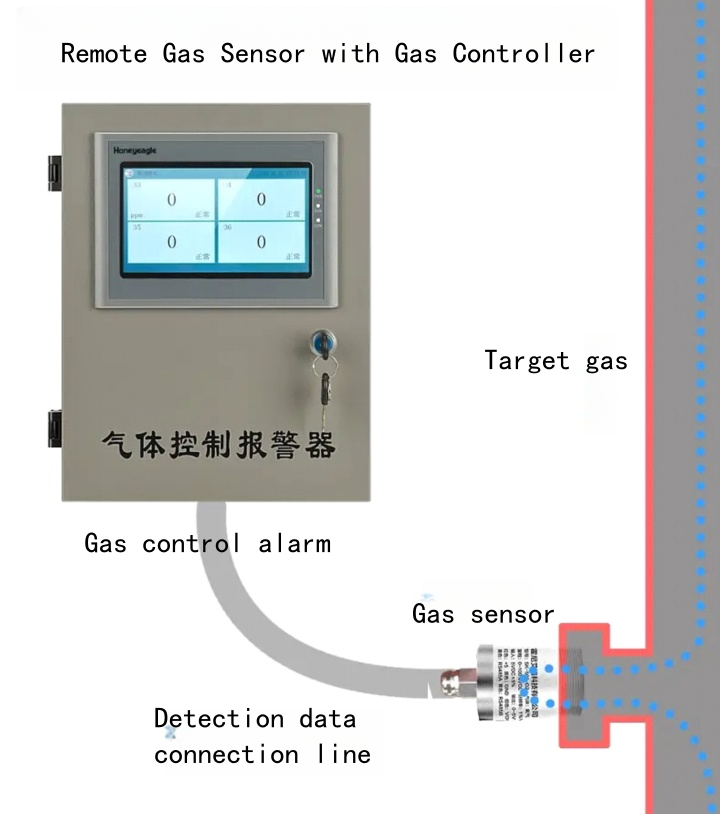

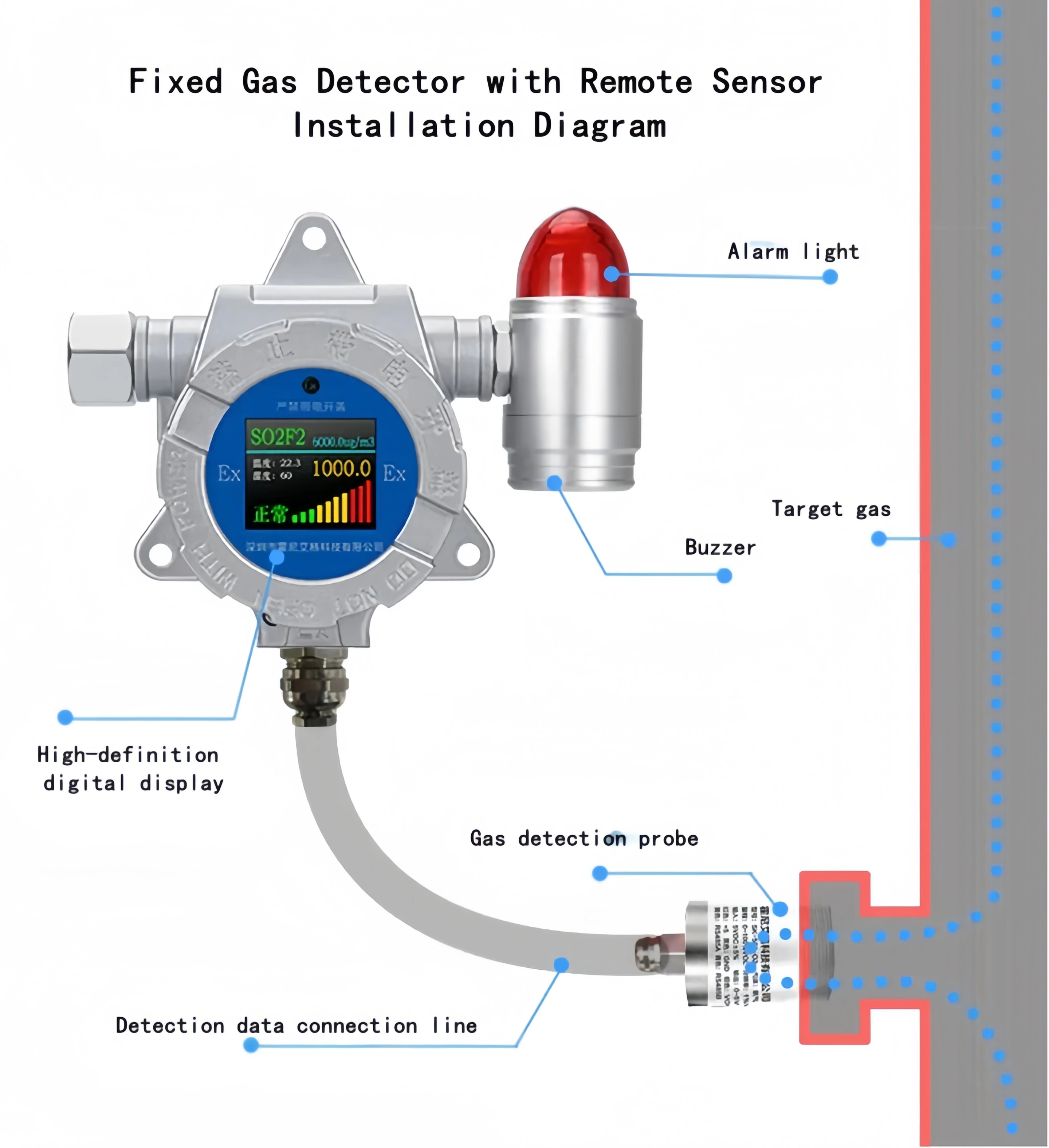

Fixed Gas Detector with Remote Sensor is a gas detection device with a display meter and a detection sensor probe separated. It is also called a split gas leak alarm, Remote gas detector, split gas sensor, etc. Its biggest feature is that the external extension tube can realize long-distance gas detection.

The length of the split connection line is 30cm~10 meters. At present, the split gas detector is mainly used in some special environment applications, such as high temperature test chambers, aging chambers, mold chambers, tank area pipelines and other scenes.

Features

Fixed Gas Detector with Remote Sensor is actually the same as the online gas detector (fixed gas detector). It’s just that the connection method of the detector is slightly different. Sino-Inst can extend the sensor part of the gas detector according to the needs of the user, so it is convenient to install and use in different locations.

If it is a high-temperature gas detector, the sensor part of the detector and the circuit board connection part use a high-temperature resistant cable, so there is no need to worry about circuit damage.

Advantages include:

- The display and the detection sensor probe are separate. The sensor head can be placed in a difficult-to-reach or dangerous location, and the operator can monitor the gas concentration at a safe distance.

- If the sensor needs to be replaced or calibrated, only the sensor head needs to be handled without moving the entire device.

- It also has functions such as on-site data display, explosion-proof sound and light alarm, detection concentration signal conversion and transmission, and relay output control.

- It can provide 4-20mA standard signal, RS485 signal, voltage signal, and switch signal. It is convenient to connect with various control alarms, PLC, DCS and other control systems to realize remote monitoring and data transmission.

- It can be operated by buttons or infrared remote control according to actual needs;

- The display control unit usually has multiple functions. Such as data recording, alarm setting, display of gas concentration, etc.

- Sensor expiration, over-concentration alarm, over-temperature alarm, fault alarm, instrument calibration reminder function, etc.;

- For certain environmental applications, the instrument can realize zero point automatic correction function;

- It can be customized with temperature, humidity detection and display.

Oxygen detectors are widely used in industrial production safety, laboratories, environmental monitoring and other fields. Especially in limited space operations, confined environments, high-altitude operations and other occasions. It is of great significance to ensure personnel safety.

Specifications

| Measuring range | 0-1000/2000/5000/10000PPM…etc.; 0-5%, 0-10%, 0-20%, 0-50%, 0-100%VOL. |

| Display unit | ppm, mg/m3, ppb, pphm, %VOL, %LEL (partially switchable) |

| Resolution | 1PPM, 0.1%VOL, 0.1%LEL |

| Accuracy | <±3%(F.S); |

| Detection principle | Electrochemical |

| Detection gas | Toxic and harmful gases (see gas list for details) |

| Repeatability | ≤±2% |

| Polarization time | 6 hours |

| T90 response time | <30 seconds |

| Self-diagnosis time | 2 times/second |

| Calibration | Every 4-8 months |

| Zeroing | Every 3-6 months |

| User interface | Infrared remote control |

| Working temperature | Customizable: -40℃~70℃ (ordinary catalytic combustion principle sensor) -40℃~270℃ (special catalytic combustion) -40℃~50℃ (electrochemical) -20℃~50℃ (pid principle sensor) -20℃~50℃ (infrared/fluorescence gas sensor) -40℃~70℃ (thermal conductivity principle sensor) -40℃~420℃ (zirconia principle oxygen sensor) sensor) |

| Working pressure | Normal standard atmospheric pressure ±10%; 0.08~0.6MPa (thermal conductivity principle sensor) 0.02~0.36MPa (zirconia principle oxygen sensor) |

| Working humidity | 0-95%RH (non-condensing) |

| Output signal | 4-20mA, RS485 |

| Connection | Analog three-wire, four-wire |

| Display | LCD backlight display, gas concentration, alarm display |

| Explosion-proof grade | Ex d IIC T6 Gb |

| Protection grade | IP66 |

| Standard configuration | Detector host, remote control, origin manual |

| Optional configuration | Sound and light alarm lamp |

| Casing material | Main body: alloy (anti-corrosion and anti-oxidation surface treatment) or stainless steel. Probe: anti-corrosion alloy or 316L stainless steel |

What Gases Can The Remote Gas Detector Detect?

Currently, some common gases can be detected, and several gases can be detected at the same time. In this way, there is no need to buy multiple single gas detectors.

| List of measurable gases This sensor can measure toxic gases or flammable gases | ||||

| Gases to be tested | Measuring range | Optional range | Resolution | Response time |

| Combustible EX | 0-100%LEL | 0-100%VOL | 1%LEL/1%VOL | ≤15S |

| Carbon monoxide CO | 0-100% ppm | 0-500/2000/5000ppm | 0.1/ppm | ≤15S |

| Methane CH4 | 0-100%VOL | 0-100%VOL | 1%VOL/0.1VOL | ≤20S |

| Ethanol C2H5OH | 0-100%LEL | 0-100%VOL | 1%LEL/0.1VOL | ≤20S |

| Hydrogen H2 | 0-100%LEL | 0-100%ppm | 1%LEL/1ppm | ≤20S |

| Acetylene C2H2 | 0-100%LEL | 0-100%VOL | 1%LEL/ppm | ≤20S |

| Oxygen 02 | 0-25%VOL | 0-30%VOL | 0.1%VOL | ≤15S |

| Ozone 02 | 0-10ppm | 0-20/100ppm | 0.01ppm/0.1ppm | ≤20S |

| Hydrogen sulfide H2S | 0-100ppm | 0-50/200/1000ppm | 1/0.1ppm | ≤15S |

| Nitrogen N2 | 0-30%VOL | 0-30%VOL/100%VOL | 1/0.1ppm | ≤20S |

| Hydrogen H2 | 0-100%LEL | 0-5000/10000ppm | 1/0.1ppm | ≤20S |

| Chlorine CL2 | 0-20ppm | 0-10/1 00 ppm | 0.1ppm | ≤20S |

| Ammonia NH3 | 0-100%ppm | 0-50/500/1000pm | 1/0.1ppm | ≤20S |

| Formaldehyde | 0-100% ppm | 0-50/100ppm | 1/0.1ppm | ≤20S |

| Sulfur dioxide SO2 | 0-100%LEL | 0-50/1000ppm | 0.1/1ppm | ≤20S |

| Nitric oxide NO | 0-250ppm | 0-500/1000ppm | 1 ppm | ≤20S |

| Carbon dioxide NO2 | 0-20ppm | 0-50/1000ppm | 1/0.1ppm | ≤20S |

| Nitrous oxide | 0-20ppm | 0-50/1000ppm | 1/0.1ppm | ≤20S |

| Carbon dioxide | 0-2000ppm | 0-5000-50000ppm | 1/0/0.1ppm | ≤20S |

| Arsine | 0-10ppm | 0-5/10/50/100ppm | 0.01/0.01ppm | ≤20S |

| Xylene, toluene | 0-20ppm | 0-5/10/50/100ppm | 0.01/0.01ppm | ≤20S |

| HCL | 0-20ppm | 0-20/50/100ppm | 0.1/0.01ppm | ≤20S |

| Other gases are not listed completely. Please contact our sales engineer to confirm! | ||||

Featured Applications

Fixed Gas Detector with Remote Sensor is mainly used in environments where data needs to be viewed outdoors for confined space detection. It also has on-site data display function, explosion-proof sound and light alarm function, detection concentration signal conversion and transmission function, relay output control and other functions.

Suitable for use in incubators, confined spaces, and non-contact gas monitoring environments. The sampling method can be set to a pump suction type by adding an air pump, and changes can be made according to the actual requirements of the site.

- Industrial field: widely used in petroleum and petrochemical, chemical plants, smelters, steel plants, coal plants, thermal power plants and other industries. Used to monitor the oxygen concentration in the production process. Prevent safety accidents such as explosions and fires.

- Medical field: In the intensive care unit, operating room, ambulance and other places of the hospital, it is used to monitor the oxygen supply of patients to ensure the safety of patients.

- Scientific research field: In scientific research laboratories, it is used for gas composition analysis and control in various experimental processes to ensure the accuracy and reliability of experimental results.

- Other fields: It can also be used in environmental monitoring, school scientific research, building construction, fire alarm, sewage treatment, garbage treatment plants, tunnel construction, oil pipelines, gas stations and other places. Ensure personnel safety and normal operation of equipment.

Selection Guide

- Detection range: Select the appropriate detection range according to actual use requirements. Common ranges include 0-30% VOL, 0-50% VOL, 0-100% VOL, etc.

- Accuracy requirements: For occasions with high accuracy requirements, high-precision detectors should be selected. Products with an accuracy of ±3% can generally meet most application requirements.

- Protection level: Depending on the use environment, select a detector with a corresponding protection level. For example, products with a protection level of IP66 or higher can prevent water splashes and dust from entering the instrument.

- Function requirements: Select a detector with corresponding functions according to actual use requirements. Such as whether data recording, wireless transmission, alarm functions, etc. are required. If remote monitoring and data management are required, products with wireless transmission functions such as GPRS/4G/WIFI can be selected.

Sino-Inst Fixed Gas Detector with Remote Sensor meets the requirements of industrial field safety monitoring for equipment reliability and diversified gas types. This design allows the split gas detector to be used in some special occasions and confined spaces in addition to conventional applications, giving users more choices.

The gas concentration monitored on site can be converted into a standard 4-20mA signal output or RS485 output. It is a split gas detection instrument with LCD field display suitable for factory applications and plug-and-play sensor replacement.

If you need gas monitoring or customized gas detection solutions, please feel free to contact our sales engineers!